High-Speed PE PP double wall corrugated pipe making machine/extrusion line(90-1200mm).

New Type PE PP double wall corrugated pipe making machine/extrusion line(90-1200mm).

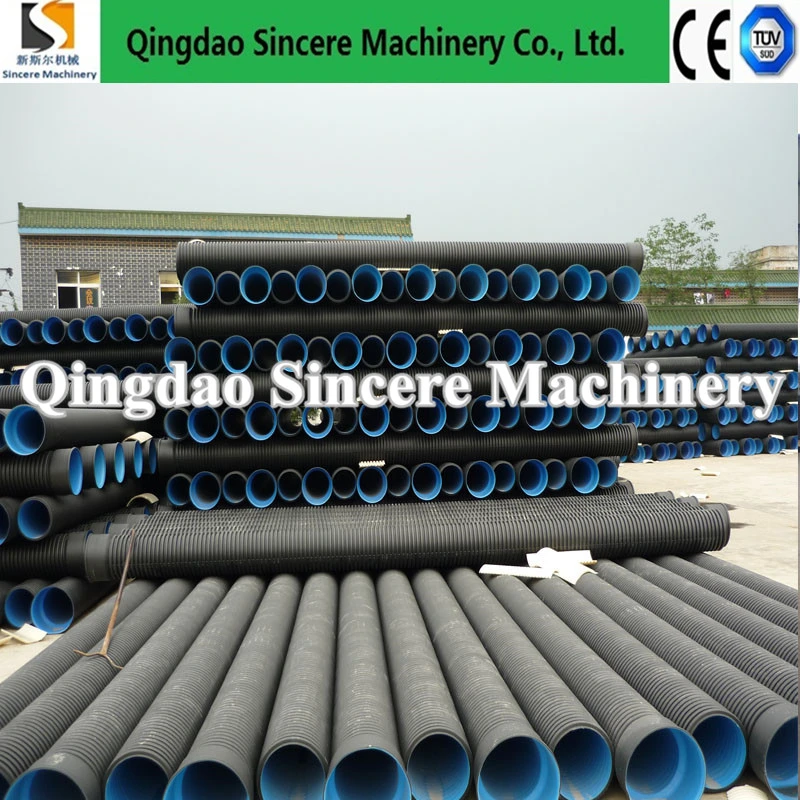

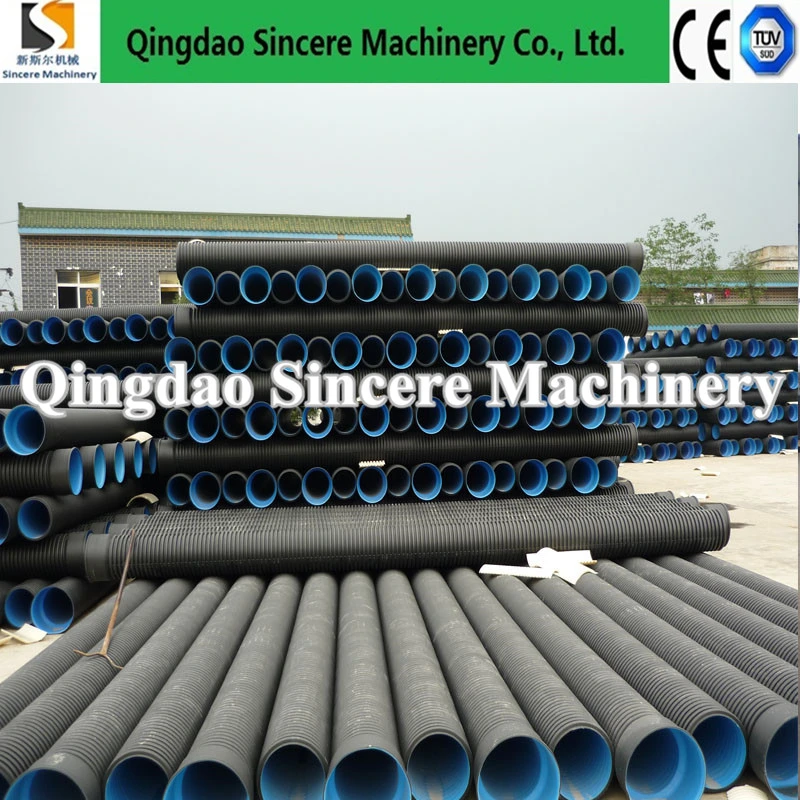

Diameters: 90-300mm,110-600mm,200-800mm,300-1000mm,600-1200mm1. HDPE double-walled corrugated pipe application:

Single screw extruders with big L\D, and Long die-head mould and calibrator.

New Type PE PP double wall corrugated pipe making machine/extrusion line(90-1200mm).

Diameters: 90-300mm,110-600mm,200-800mm,300-1000mm,600-1200mm

1. HDPE double-walled corrugated pipe application:

HDPE / PP double wall corrugated pipe is widely used as drain pipe. The company absorbs foreign advanced technology, independent research and development of the HDPE double wall corrugated pipe production line, with a number of patented technologies. Our new high-speed PE | PP double-wall corrugated pipe production line, the use of new high-performance single-screw extruder, forming machine using horizontal structure, shuttle drive, sealed water-cooled, online flaring, high degree of automation, stable operation, large output.

2. PE / PP double wall corrugated pipe production line, can be used to produce ID90-ID1200 specifications of the single-walled, double-wall corrugated pipe (with Pipe Belling), three-wall corrugated pipe, different shapes and special requirements of special-shaped bellows.

3. Main technical parameters:

| Line Model | SMSG-300 | SMSG-600 | SMSG-800 | SMSG-1000 | SMSG-1200 |

| the diameter range (DN|ID)(mm) | 90mm-300mm | 110mm-600mm | 200mm-800mmmm | 300mm-1000mm | 600mm-1200mm |

| Mold number (pair) | 36 | 36 | 36 | 39 | 39 |

| Max. Operating speed (m\min) | 18 | 6.5 | 5.5 | 3.5 | 1.8 |

| Total power(kw) | 250 | 395 | 650 | 980 | 1350 |

| Max. output(kg\h) | 600 | 1350 | 1600 | 1900 | 2100 |

| Dimension (mm) Length*Width*Height | 27*3.5*2.8m | 27*5.5*3.8m | 29*6.8*4.0m | 32*7.6*4.2m | 35*8.5*4.5m |

Single screw extruders with big L\D, and Long die-head mould and calibrator.

High-speed corrugator machine, using high-qulity Aluminum module.

Water cooling tank, Automatic cutting machine, stacker.