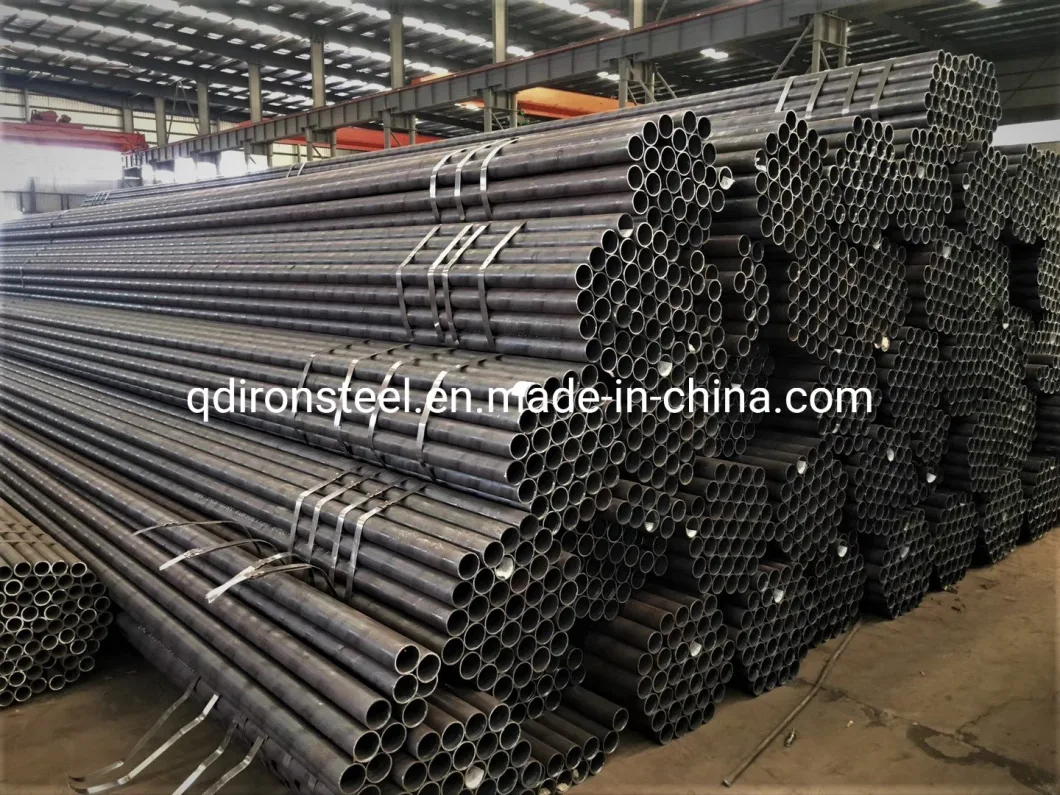

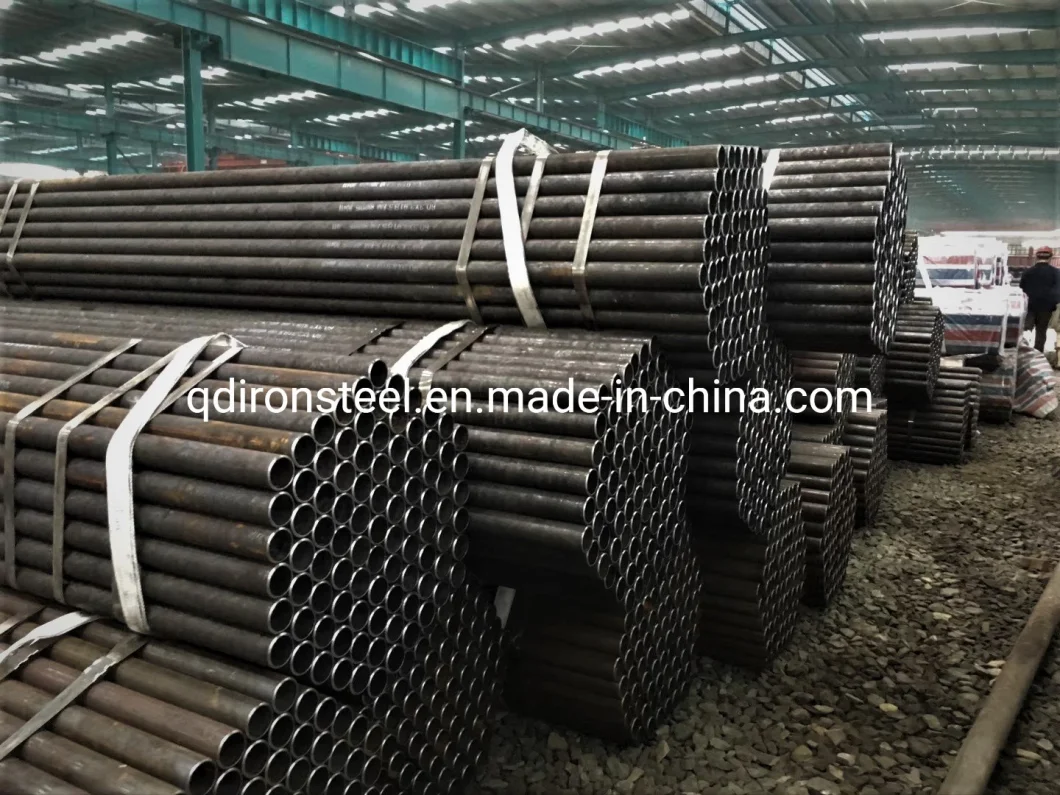

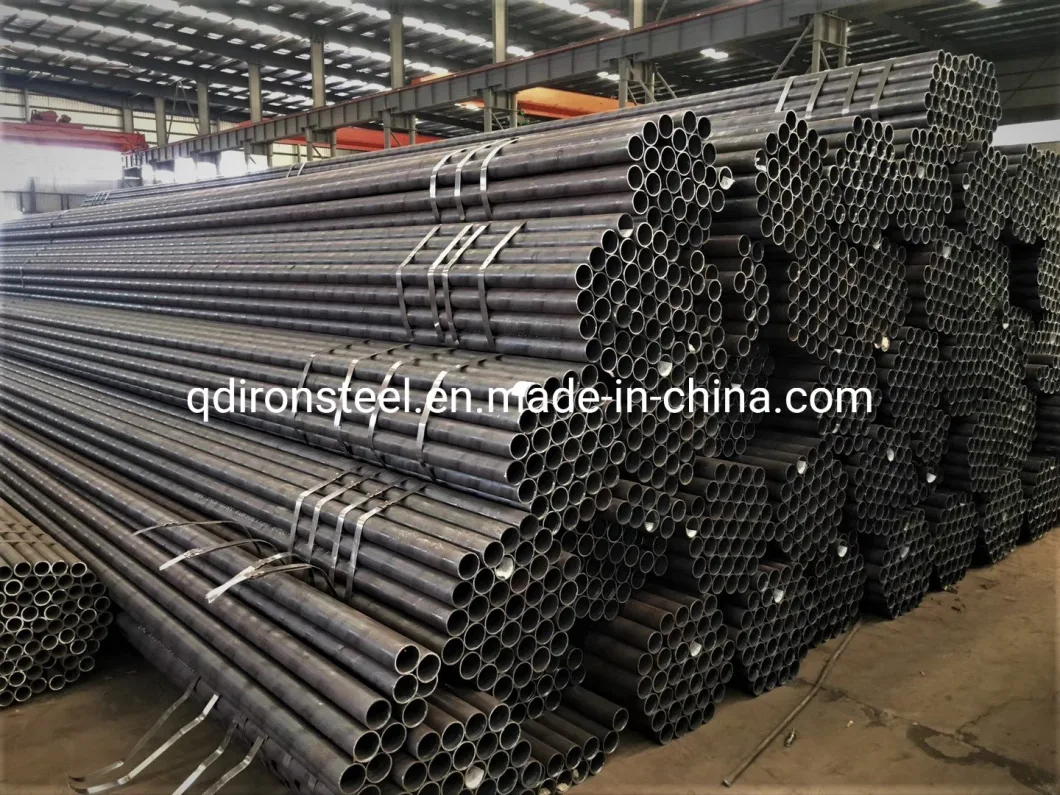

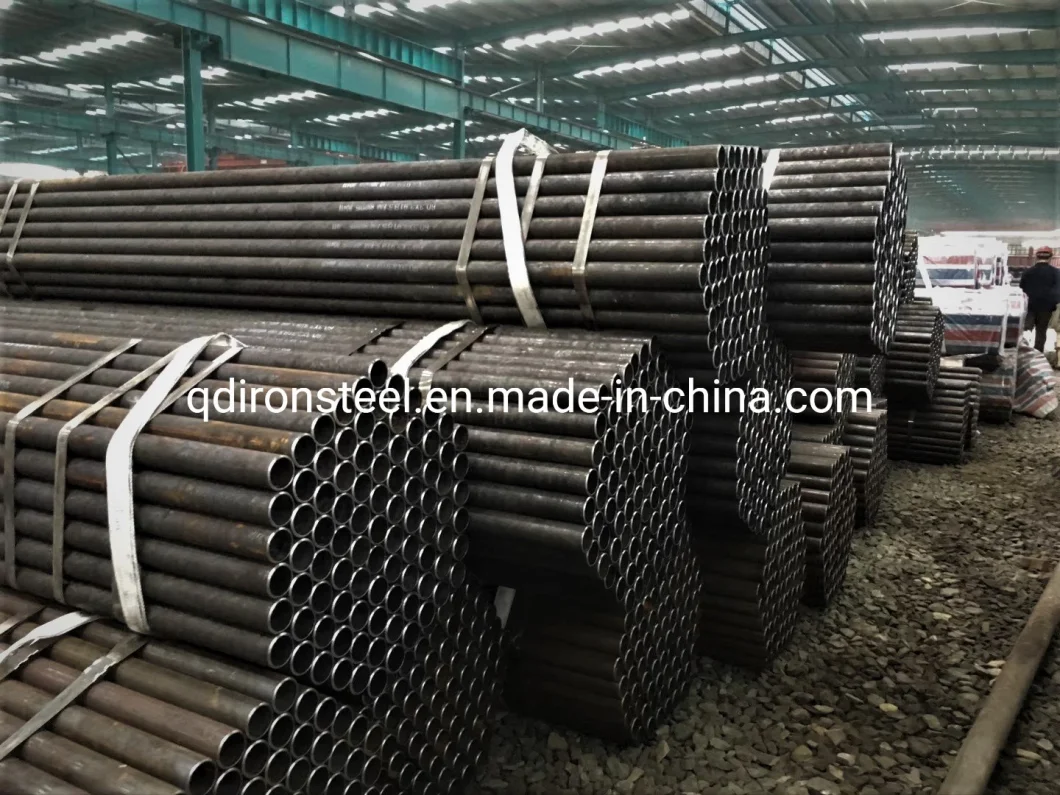

Tandem Rolling Seamless Steel Pipe hot rolling seamless steel pipe

Standard: ASTM A106/ASTM A53/ASME SA106/ DIN1629/DIN2448/ASME SA210 etc

Steel grade: Gr.B, AISI SAE1020, 1045, ST52, ST44, ST37, 15CrMo, 42CrMo, other Carbon steel or Alloy materials.

Tandem rolling production line from 42mm to 610mm, with big production capacity and good quality.

More than 30 Thousands tons of Hot Rolling Seamless Pipes keep in Stock All the Year Round!

More than 30 Thousands tons of Hot Rolling Seamless Pipes keep in Stock All the Year Round!

Chemical Composition for carbon seamless pipe fluid conveying pipe

Physical Property of carbon seamless pipe fluid conveying pipe

Chemical composition of high pressure boiler steel pipe

Standard: ASTM A106/ASTM A53/ASME SA106/ DIN1629/DIN2448/ASME SA210 etc

Steel grade: Gr.B, AISI SAE1020, 1045, ST52, ST44, ST37, 15CrMo, 42CrMo, other Carbon steel or Alloy materials.

Tandem rolling production line from 42mm to 610mm, with big production capacity and good quality.

Chemical Composition for carbon seamless pipe fluid conveying pipe

| Standard | Steel grade | Chemical Composition (%) | ||||||||

| C | Si | Mn | P | S | Cu | Ni | Mo | Cr | ||

| GB/T8162 | 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.15 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 35 | 0.32-0.40 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| Q345 | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | / | ≤0.25 | |

| 15CrMo | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.30 | 0.40-0.55 | 0.80-1.10 | |

| ASTM A53 | A | ≤0.25 | / | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.40 |

| ASME SA53 | B | ≤0.30 | / | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.40 |

| Standard | Steel grade | Tensile Strength (Mpa) | Yield strength (Mpa) | Elongation (%) | |

| GB/T8162 | 10 | ≥335 | ≥205 | ≥24 | |

| 20 | ≥390 | ≥245 | ≥20 | ||

| 35 | ≥510 | ≥305 | ≥17 | ||

| 45 | ≥590 | ≥335 | ≥14 | ||

| Q345 | ≥490 | ≥325 | ≥21 | ||

| 15CrMo | ≥440 | ≥245 | ≥22 | ||

| ASTM A53 | A | ≥330 | ≥205 | ASTM A53 view of the talbe | |

| ASME SA53 | B | ≥415 | ≥240 | ASME SA 53 view of the table | |

Chemical composition of high pressure boiler steel pipe

| Standard | Steel grade | C | Si | Mn | P | S | Cr | Mo | Cu | Ni | V | Al | W | Ti | Nb | N |

| GB 3087 | 10 | 0.07-0.13 | 0.17-0.37 | 0.38-0.65 | ≤0.03 | ≤0.03 | 0.3-0.65 | / | ≤0.25 | ≤0.3 | / | / | / | / | / | / |

| 20 | 0.07-0.23 | 0.17-0.37 | 0.38-0.65 | ≤0.03 | ≤0.03 | 0.3-0.65 | / | ≤0.25 | ≤0.3 | / | / | / | / | / | / | |

| GB 5310 | 20G | 0.17-0.24 | 0.17-0.37 | 0.38-0.65 | ≤0.03 | ≤0.03 | ≤0.25 | ≤0.15 | ≤0.2 | ≤0.25 | / | / | / | / | / | / |

| 20MnG | 0.17-0.24 | 0.17-0.37 | 0.7-1.0 | ≤0.03 | ≤0.03 | ≤0.25 | ≤0.15 | ≤0.2 | ≤0.25 | / | / | / | / | / | / | |

| 25MnG | 0.22-0.3 | 0.17-0.37 | 0.7-1.0 | ≤0.03 | ≤0.03 | ≤0.25 | ≤0.15 | ≤0.2 | ≤0.25 | / | / | / | / | / | / | |

| 15CrMoG | 0.12-0.18 | 0.17-0.37 | 0.4-0.7 | ≤0.03 | ≤0.03 | 0.8-1.1 | 0.4-0.55 | ≤0.2 | ≤0.3 | / | / | / | / | / | / | |

| 12Cr2MoG | 0.08-0.15 | ≤0.5 | 0.4-0.7 | ≤0.03 | ≤0.03 | 2.0-2.5 | 0.9-1.2 | ≤0.2 | ≤0.3 | / | / | / | / | / | / | |

| 12Cr1MoVG | 0.08-0.15 | 0.17-0.37 | 0.4-0.7 | ≤0.03 | ≤0.03 | 0.9-1.2 | 0.25-0.35 | ≤0.2 | ≤0.3 | 0.15-0.3 | / | / | / | / | / | |

| 12Cr2MoWVTiB | 0.08-0.15 | 0.45-0.75 | 0.45-0.65 | ≤0.03 | ≤0.03 | 1.6-2.1 | 0.5-0.65 | ≤0.2 | ≤0.3 | 0.28-0.42 | / | 0.3-0.55 | 0.08-0.18 | B0.002-0.008 | / | |

| 10Cr9Mo1VNb | 0.08-0.12 | 0.2-0.5 | 0.3-0.6 | ≤0.02 | ≤0.01 | 8.0-9.5 | 0.85-1.05 | ≤0.2 | ≤0.4 | 0.18-0.25 | ≤0.04 | / | / | 0.06-0.1 | 0.03-0.07 | |

| ASME SA210 | SA210 A1 | ≤0.27 | ≥0.1 | ≤0.93 | ≤0.03 | ≤0.03 | / | / | / | / | / | / | / | / | / | / |

| SA210 C | ≤0.35 | ≥0.1 | 0.29-1.06 | ≤0.03 | ≤0.03 | / | / | / | / | / | / | / | / | / | / | |

| ASME SA213 | SA213 T11 | 0.05-0.15 | 0.5-1.0 | 0.3-0.6 | ≤0.03 | ≤0.03 | 1.0-1.5 | 0.5-1.0 | / | / | / | / | / | / | / | / |

| SA213 T12 | 0.05-0.15 | ≤0.5 | 0.3-0.6 | ≤0.03 | ≤0.03 | 0.8-1.25 | 0.44-0.65 | / | / | / | / | / | / | / | / | |

| SA213 T22 | 0.05-0.15 | ≤0.5 | 0.3-0.6 | ≤0.03 | ≤0.01 | 1.9-2.6 | 0.87-1.13 | / | / | / | / | / | / | / | / | |

| SA213 T23 | 0.04-0.1 | ≤0.5 | 0.1-0.6 | ≤0.03 | ≤0.03 | 1.9-2.6 | 0.05-0.3 | / | / | / | ≤0.03 | 1.45-1.75 | / | 0.02-0.08 | ≤0.04 | |

| SA213 T91 | 0.08-0.12 | 0.2-0.5 | 0.3-0.6 | ≤0.02 | ≤0.01 | 8.0-9.5 | 0.85-1.05 | / | ≤0.4 | 0.18-0.25 | ≤0.015 | / | / | 0.06-0.1 | 0.03-0.07 | |

| SA213 T92 | 0.07-0.13 | ≤0.5 | 0.3-0.6 | ≤0.02 | ≤0.01 | 8.5-9.5 | 0.3-0.6 | / | ≤0.4 | 0.15-0.25 | ≤0.015 | 1.5-2.0 | / | 0.04-0.09 | 0.03-0.07 | |

| DIN 17175 | ST45.8-III | ≤0.21 | 0.1-0.35 | 0.4-1.2 | ≤0.04 | ≤0.04 | / | / | / | / | / | / | / | / | / | / |

| 15Mo3 | 0.12-0.2 | 0.1-0.35 | 0.4-0.8 | ≤0.035 | ≤0.035 | / | 0.25-0.35 | / | / | / | / | / | / | / | / | |

| 13CrMo44 | 0.0-0.18 | 0.1-0.35 | 0.4-0.7 | ≤0.035 | ≤0.035 | 0.7-1.1 | 0.45-0.65 | / | / | / | / | / | / | / | / | |

| 10CrMo910 | 0.08-0.15 | ≤0.5 | 0.3-0.7 | ≤0.025 | ≤0.025 | 2.0-2.5 | 0.9-1.1 | ≤0.3 | ≤0.3 | / | ≤0.015 | / | / | / | / |